Limited Slip Differentials (LSDs) are essential upgrades for drivers who demand better control, traction, and drivetrain balance. Whether installed for motorsport, off-road capability, or enhanced street performance, an LSD must be precisely integrated into the vehicle’s drivetrain to deliver its intended benefits.

But here’s the problem: even a high-end LSD can quickly become a liability if it’s installed incorrectly. From minor oversights to major mechanical missteps, these errors can quietly undermine your differential’s effectiveness—or outright destroy it.

If you’re investing in performance, especially in a vehicle with a modified engine block or high-output powertrain, avoiding these critical mistakes is non-negotiable. Let’s take a closer look at ten installation errors that have ruined far too many differentials.

1. Ignoring Break-In Procedures

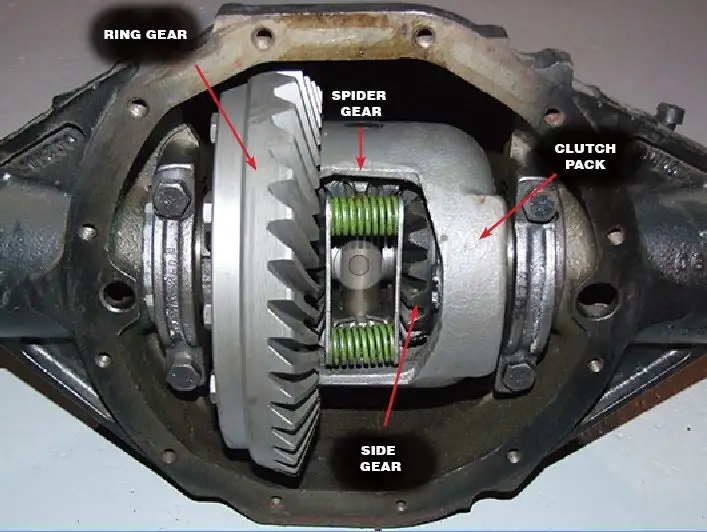

A brand-new clutch-type LSD isn’t ready for peak performance right out of the box. Failing to follow a proper break-in process can lead to premature wear and inconsistent locking behavior. Many installers mistakenly skip this phase, assuming normal driving will “wear it in.”

Without controlled break-in—usually involving slow figure-eights and gentle load transitions—the friction plates may glaze or wear unevenly. This can permanently reduce locking response or generate unwanted chatter during turns.

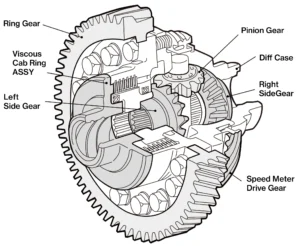

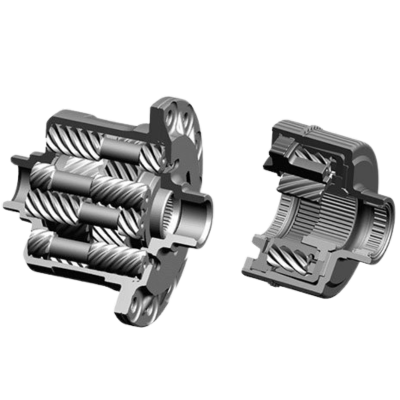

It’s worth noting that Torsen-style LSDs do not require a traditional break-in procedure. These units rely on helical gears rather than friction plates, so there’s no surface bedding needed. However, even for gear-based LSDs, it’s still advisable to avoid harsh driving during the first 100 to 200 kilometers. This gives the gears time to settle under moderate load and ensures proper lubrication distribution throughout the differential. Also, make sure to use the correct gear oil—Torsen LSDs typically do not require friction modifiers, and using oil with additives intended for clutch-type LSDs can actually reduce effectiveness.

2. Using the Wrong Gear Oil or Skipping Friction Modifiers

This is one of the most damaging yet common errors. Not all gear oils are LSD-compatible, and many performance differentials require a specific viscosity range and additive package.

Omitting friction modifiers or using incompatible fluids can result in harsh operation, noisy engagement, and internal wear. In extreme cases, the oil can overheat, compromising both the LSD and the surrounding components—particularly under high loads from upgraded engine blocks or forced induction systems.

3. Incorrect Torque on Carrier Bearings or Ring Gear Bolts

Precision torque settings aren’t optional—they’re essential. Under-torqued ring gear bolts or improperly set carrier bearing preload can cause movement under load, misalignment, or gear failure.

Assuming “tight enough” is good enough is a fast path to gear whine, overheating, and catastrophic differential failure. Each LSD model has its own torque specs. Always consult the manufacturer’s data before final assembly.

4. Skipping Gear Pattern Verification

Even a perfect LSD installation can fall apart if the ring and pinion gears aren’t set up properly. After assembly, the contact pattern must be checked and verified to ensure optimal mesh. Skipping this step can create excess noise, heat, and wear.

A poor gear pattern not only reduces lifespan—it directly undermines the LSD’s effectiveness. You’re not just installing a new part; you’re tuning a system that must work together under extreme stress.

5. Overlooking Supporting Components Like the Engine Block

LSD performance doesn’t happen in isolation. If your LSD is going behind a newly built engine block or a power-enhanced drivetrain, the stresses will be significantly higher.

Failing to inspect components such as driveshafts, axle shafts, or transmission mounts can lead to torque inconsistencies, vibration, or even differential housing failure. The LSD is only as reliable as the system surrounding it.

6. Improper Shim Selection and Placement

Backlash and preload are finely tuned through the use of shims. Guessing shim sizes or reusing factory shims from an open differential is a critical error that affects engagement and longevity.

Lack of proper tooling—such as dial indicators—leads many installers to eyeball settings, which introduces slop, excessive drag, or internal damage. With LSDs, “close enough” isn’t close enough.

7. Using Weak Axle Shafts or Stock Driveshafts

A high-performance LSD transfers torque more aggressively than an open differential. That torque has to go somewhere—and often, it finds the weakest point in your drivetrain.

If you’re running stock axles in a high-power build, especially one with a modified engine block, you’re playing with fire. Twisted splines, shattered CV joints, and broken driveshafts are the predictable result. Upgrading these components during LSD installation is not just smart—it’s essential.

8. Ignoring Manufacturer Preload Recommendations

Different LSDs require different preload configurations. Some clutch-based units require high static preload for aggressive lock-up, while others are designed for smooth engagement under torque.

Applying preload arbitrarily—or cranking it beyond spec in pursuit of more “bite”—will only lead to heat, noise, and premature wear. Follow the preload guidance exactly as specified, or risk destroying the plates before you’ve even enjoyed the first drive.

9. Installing in an Incompatible Housing

Not every housing is ready to accept an aftermarket LSD. Differences in spline count, carrier dimensions, or housing depth can result in poor alignment or even component interference.

Installers who assume compatibility without verification often end up with clearance issues, oil starvation, or binding under load. If the housing doesn’t match, modification or full replacement may be necessary.

10. Skipping Final Inspection and Test Drives

Even when everything appears perfect, the job isn’t done until you test the system. Turning the wheels by hand, checking torque resistance, and conducting a low-speed road test can catch subtle issues before they become major failures.

In performance builds, particularly those built around high-output engine blocks, final inspection is the difference between reliable torque distribution and drivetrain disaster. Don’t rely on assumptions—verify everything.

Final Thoughts

A Limited Slip Differential is one of the most transformative drivetrain upgrades you can make. But installing it incorrectly is worse than not installing it at all. The errors outlined above have destroyed differentials, compromised builds, and left drivers chasing performance problems for months.

If your build includes a reinforced engine block or significant horsepower upgrades, the importance of precision installation increases dramatically. Proper setup ensures that your LSD performs exactly as it should—delivering traction, balance, and control when you need it most.

Before you torque that last bolt, ask yourself: did you get every step right?