When it comes to off-road driving, using differential lockers (commonly referred to as “diff lockers”) can significantly enhance a vehicle’s performance. However, while they are an incredible tool in the right situation, improper use can lead to serious driveline damage, costly repairs, and even dangerous situations. This guide provides an in-depth analysis of eight situations where you should avoid using diff lockers, explains how they function, and offers best practices for safe and effective use.

What Is a Diff Locker and How Does It Work?

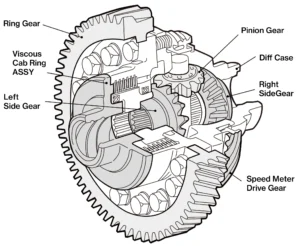

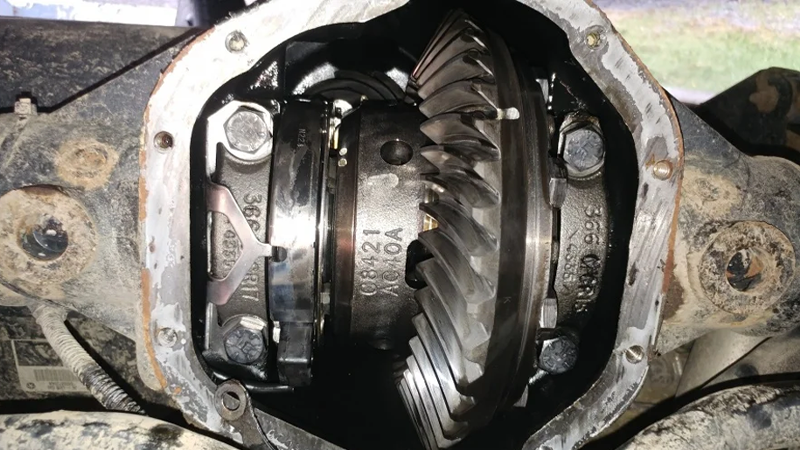

To fully understand when not to use diff lockers, it’s important to first grasp what they do and why they are so effective. A differential allows the wheels on an axle to rotate at different speeds, which is crucial when turning since the outer wheels travel a greater distance than the inner ones. However, this feature can become a disadvantage when off-road.

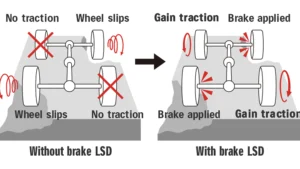

When one wheel loses contact with the ground (such as crossing deep ruts, rocky obstacles, or wombat holes), the open differential sends power to the wheel with the least resistance — usually the one that’s in the air. This results in wheel spin and a loss of forward momentum.

A diff locker solves this problem by locking both wheels on an axle together, forcing them to rotate at the same speed regardless of traction differences. This ensures that both wheels continue to turn, maintaining forward momentum even when one wheel has no ground contact. While this provides excellent traction in tricky off-road situations, it also introduces mechanical stress that must be managed carefully.

1. High Stress and High Load Situations at Speed

Momentum plays a significant role in off-road driving, especially when navigating steep climbs or loose terrain. However, combining high momentum with locked differentials creates immense stress on the drivetrain components. This is particularly dangerous when towing heavy loads uphill or when attacking obstacles aggressively at speed.

For instance, towing a trailer up a steep incline with lockers engaged can quickly overload the driveline, leading to broken axles or snapped components. The extra traction from locked diffs might help in the moment, but the cumulative stress will eventually cause catastrophic failures. Controlled, steady driving with careful throttle application is far safer than using brute force.

2. High Traction, Smooth Off-Road Surfaces

On high-traction, relatively smooth off-road surfaces — such as compact dirt roads or rocky plateaus where all wheels maintain good contact with the ground — using diff lockers can cause unnecessary drivetrain binding, also known as “wind-up.” With no way for the wheels to rotate at different speeds during minor turns or variations in terrain, bind-up accumulates in the driveline.

The symptoms include increased tire wear, steering difficulties, and ultimately, driveline component failure. In these situations, an open differential or limited-slip differential (LSD) is more appropriate, allowing natural differentiation between wheel speeds.

3. High Traction, Uneven Surfaces: Selective Use of Front Lockers

In certain high-traction but uneven terrains, such as rock crawling or climbing over step-ups, diff lockers can be invaluable. These surfaces often lift one or more wheels off the ground, and lockers ensure consistent forward motion. However, selective use of the front locker is crucial.

Engaging the front locker while steering uphill on a winding trail can severely limit your ability to turn. This happens because locking the front axle reduces the difference in wheel rotation needed for smooth cornering. If you attempt to make a turn with the front locker engaged, you risk binding, losing steering control, or becoming stuck mid-turn.

Best practice: use the rear locker as your primary aid and engage the front locker only when absolutely necessary, disengaging it as soon as the obstacle has been cleared.

4. Descending Hills: Rear Locker Only

When descending steep hills, traction is critical to maintaining control and preventing slides. Using low range gears combined with the rear locker helps keep the vehicle straight and stable. The locked rear axle prevents individual wheel spin, allowing the rear tires to anchor the vehicle firmly on the descent.

However, never engage the front locker while descending. Gravity shifts most of the vehicle’s weight onto the front axle, which is inherently weaker than the rear. Engaging the front locker increases driveline load, restricts steering, and dramatically reduces your ability to control direction. This combination can easily lead to dangerous situations, especially on loose or uneven downhill terrain.

Rule of thumb: Rear locker engaged, front locker disengaged when descending steep grades.

5. Engaging Lockers in High Range

Many factory-installed lockers only allow engagement when the vehicle is in low-range four-wheel drive. Some aftermarket systems, however, permit locker engagement in high-range (2H or 4H). While this might seem like added flexibility, it’s generally not advisable.

Using lockers at higher speeds multiplies the shock loads transmitted through the driveline. For example, quick gear changes in high-range with lockers engaged produce sudden torque spikes, increasing the risk of snapping axles, damaging U-joints, or breaking differential gears. The front locker is especially dangerous at speed, as steering control is compromised significantly.

Safe practice: Use lockers only in low-range (4L), at slow speeds, and on technical sections where careful control is paramount.

6. Sudden Acceleration and High-Speed Sections

Sudden bursts of acceleration with lockers engaged amplify the torque forces within your driveline. Lockers excel in slow, technical crawling, where maintaining constant wheel speed on both sides of the axle is an advantage.

If a section requires high speed or aggressive momentum to clear — such as powering through a sandy washout or climbing a dune — lockers may not be needed. In these scenarios, speed itself provides the necessary inertia to maintain forward motion. Lockers should be reserved for areas where crawling and precision are more effective than brute speed.

Pro tip: Lockers are for traction control, not for aggressive driving. Use them where control and slow progress are more critical than speed.

7. Using Lockers When Wedged or Stuck

One of the most common mistakes off-roaders make is engaging lockers when the vehicle is severely wedged or pinned between obstacles. If the vehicle is not moving, locking the diffs only increases tension within the driveline, locking in all the binding forces without providing a release path.

Before engaging lockers when stuck, always inspect the situation. Determine whether lockers will assist or simply amplify the binding. For example, using front lockers while fully steering-locked adds massive torsional stress on CV joints and axle shafts, often leading to breakage. Attempting to force your way out with locked diffs may cause expensive drivetrain failures.

Golden rule: Always investigate and assess before engaging lockers when stationary and jammed between obstacles.

8. Side Slopes with Loose Surfaces

Side slopes on loose sand, gravel, or shale are especially hazardous when lockers are engaged. On these angles, gravity naturally shifts weight downhill, increasing load on the lower wheels. If lockers are engaged, the upper wheels are forced to rotate equally, overriding natural wheel speed compensation.

The result is a significant increase in lateral sliding, as locked axles can’t allow the upper wheels to rotate freely. In extreme cases, this can cause the vehicle to slide sideways down the slope or even roll over.

When driving on side slopes, keeping the differentials open allows the vehicle to better adapt to varying wheel loads, minimizing lateral movement.

Important: Avoid using lockers on side slopes unless absolutely necessary for short bursts of controlled crawling.

Who Should Use Diff Lockers?

Anyone who ventures into low traction environments can benefit from diff lockers. These include:

- Muddy tracks

- Rocky trails

- Loose shale climbs

- Sand dunes

- Snow-covered paths

- Deep ruts

Types of Diff Lockers

If you’re researching lockers, you’ll encounter several types:

- Air Lockers (Pneumatic Lockers): Activated by compressed air, providing full locking capability on demand. Very popular for aftermarket installations.

- Electronic Lockers (E-Lockers): Activated via electric switch, typically found on many factory 4WD models.

- Automatic Lockers: Always engaged but automatically allow differentiation under certain conditions.

- Mechanical Lockers: Use mechanical engagement, such as manual levers or cable-actuated systems.

Conclusion

Diff lockers are among the most powerful traction aids available to off-road drivers. But like all powerful tools, they require knowledge, caution, and deliberate use. Improper application can lead to expensive damage, unsafe driving situations, and broken components.

By understanding these eight situations where lockers should be used with caution or avoided entirely, you can extend the life of your drivetrain, improve safety, and maximize your 4WD’s capability.

For serious off-road enthusiasts, investing time to learn locker operation is just as important as installing them. Always remember: slow and steady wins the off-road race.