In this article, we will explore what makes an LSD effective, the factors to consider when evaluating its quality, common installation pitfalls, and how you can ensure you’re selecting reliable components for your vehicle or business.

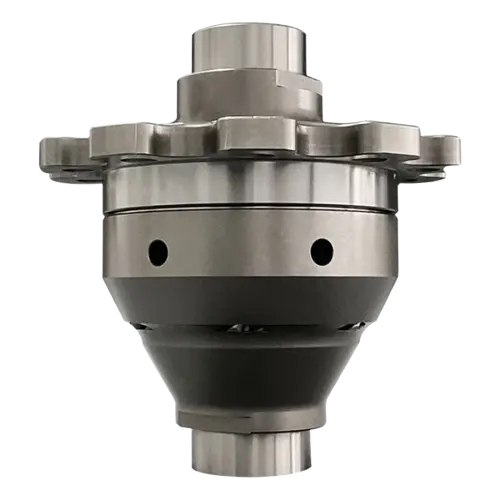

What Is a Limited Slip Differential?

There are several types of LSDs, including mechanical, clutch-based, torque-biasing, and electronic LSDs. Each type offers unique advantages and operates slightly differently:

- Mechanical LSD: Uses gears to transfer torque between wheels and improve traction. While robust, purely mechanical LSDs are relatively uncommon in modern passenger vehicles and are mostly found in specialized or older performance applications.

- Clutch-based LSD: This is the traditional design that relies on friction plates to provide resistance between wheels. It was popular in the past, especially for racing or high-performance cars, but has become less common today due to maintenance requirements and wear concerns.

- Torque-biasing LSD (Torsen): Currently one of the most widely used types, Torsen LSDs automatically adjust torque distribution based on wheel resistance, offering smooth, predictable handling and durability. Highly recommended for both performance and daily-use vehicles.

- Electronic LSD (eLSD): Uses sensors and electronic controls to simulate differential locking. eLSDs are increasingly common in modern vehicles, providing excellent flexibility and integration with vehicle stability systems. They are a strong choice for modern performance and off-road applications.

Understanding these types is the first step in evaluating LSD quality. For most modern vehicles and aftermarket applications, Torsen and eLSD systems are the preferred choices, providing reliability, smooth operation, and broad compatibility.

Why Quality Matters for LSD Performance

- Uneven Tire Wear: Low-quality differentials can distribute torque inconsistently, causing excessive wear on one wheel.

- Noise and Vibration: Inferior materials or imprecise machining can generate clunking sounds or vibration under load.

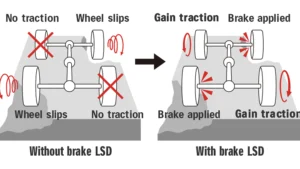

- Reduced Traction: An LSD that doesn’t engage smoothly may fail to provide the expected grip, especially under acceleration or cornering.

- Shorter Lifespan: Substandard heat treatment, low-quality steel, or improper assembly can lead to premature wear of gears and bearings.

Key Factors to Check When Evaluating LSD Quality

When assessing an LSD, there are several technical factors to consider. These elements determine how well the differential will perform under various conditions and how long it will last.

1. Gear Accuracy and Material

The precision of the gear teeth and the quality of the steel used are critical indicators of LSD quality. High-quality LSDs feature gears manufactured with tight tolerances, ensuring smooth engagement and minimal backlash. Materials such as hardened alloy steel provide the strength necessary to handle high torque loads without deformation.

2. Heat Treatment and Hardness

Proper heat treatment ensures the gears achieve the correct hardness profile, balancing wear resistance with toughness. Inadequate or uneven heat treatment can result in premature gear failure or pitting under stress. A reputable LSD manufacturer will often provide hardness specifications and quality control documentation for each component.

3. Noise and Smoothness

Noise, vibration, and harshness (NVH) are subtle indicators of build quality. A high-quality LSD engages smoothly and quietly, even under high torque. Excessive chatter or clunking during engagement may indicate poor machining, insufficient lubrication, or substandard friction materials.

4. Brand Reputation and Certification

Reliable brands provide clear specifications, testing protocols, and performance certifications. Choosing an LSD from a reputable supplier reduces the risk of receiving a defective or poorly performing unit. Look for documented testing results, OEM compliance, or industry-standard certifications.

5. Lubrication and Maintenance

Proper lubrication is essential for differential longevity. High-quality LSDs are designed to work with specific gear oils, and following the manufacturer’s maintenance schedule ensures optimal performance. Some units also include pre-filled friction plates or advanced surface coatings to reduce wear and improve smoothness.

Common Installation Mistakes That Ruin LSD Performance

- Incorrect Preload or Torque Settings: Many LSDs require precise torque settings for installation. Deviating from these specifications can cause premature wear or inconsistent engagement.

- Improper Gear Pattern Setup: Ring and pinion gear alignment is critical. Incorrect backlash or contact patterns can generate noise and reduce efficiency.

- Using the Wrong Lubricant: Not all gear oils are compatible with clutch-based or torque-biasing LSDs. Using the wrong type can lead to slippage, overheating, or accelerated wear.

- Neglecting Break-in Procedures: Some LSDs require a break-in period to allow friction plates or gears to seat properly. Skipping this step may result in uneven wear and noise.

Evaluating LSD for Business Applications

- Supply Chain Reliability: Consistent availability and clear delivery schedules ensure you can meet client demands without delays.

- After-Sales Support: Technical support, documentation, and warranty options add value and instill confidence for buyers.

- Compatibility Information: Detailed application guides, including compatible models and gear ratios, help reduce mistakes and returns.

- Pricing vs. Quality Balance: Evaluate LSDs not just by cost but by longevity, reliability, and reduced liability from failures.

Practical Tips for Selecting LSDs

- Compare Manufacturers: Look for brands with proven track records, documented testing, and industry certifications.

- Request Sample Units or Inspection Reports: Inspect friction materials, gear finish, and assembly quality before committing to bulk orders.

- Check Reviews and References: Feedback from other shops or distributors can provide insights into real-world performance.

- Understand Vehicle Application: Match the LSD type to the vehicle’s intended use—high-performance racing, off-road driving, or daily commuting.

- Plan for Maintenance and Support: Consider the ease of servicing, availability of parts, and recommended maintenance intervals.

Following these steps will help you make informed purchasing decisions and ensure the LSDs you offer meet high standards.

Conclusion

Evaluating the quality of Limited Slip Differentials requires a comprehensive approach that considers materials, manufacturing precision, heat treatment, smoothness, brand reputation, and proper installation practices. Whether you are a professional automotive supplier, a performance shop, or a vehicle enthusiast, understanding these factors ensures you can select LSDs that deliver reliable performance, longevity, and safety.

At XJXPARTS, we are a trusted factory specializing in high-quality LSDs, crown wheel and pinion gears, and other drivetrain components. Our products are engineered for precision, durability, and smooth performance. If you need reliable LSDs or other drivetrain solutions for your business, you can contact us anytime through our contact page. Our team is ready to assist with your inquiries and provide the solutions you need.