For automotive enthusiasts, the quest for speed often begins with the engine. We obsess over horsepower figures, turbocharger sizes, and intake airflow. However, seasoned drivers and engineers know that power is ultimately meaningless if it cannot be effectively transferred to the asphalt. This is the domain of the differential.

While the standard open differential found in most commuter cars is adequate for grocery runs, it is a significant bottleneck for performance. To solve the infamous “one-wheel peel” where power evaporates through the wheel with the least grip, the Limited-Slip Differential (LSD) was developed.

For decades, the debate has raged between the two primary technologies: the traditional Clutch-type LSD and the torque-sensing Torsen (or ATB) LSD. While the clutch-type unit has a storied history in motorsports, automotive engineering has evolved. Today, the Torsen differential stands out as the superior choice for the vast majority of performance applications, offering a blend of durability, sophistication, and speed that older friction-based designs simply cannot match.

Understanding the Function of the Open Differential

To appreciate why the shift toward Torsen technology has occurred, we must first understand the problem it solves. An open differential splits torque typically 50/50 between the left and right wheels. Its primary function is to allow the outside wheel to rotate faster than the inside wheel during a turn.

The flaw in this design becomes apparent under load or in low-traction scenarios. An open differential is mechanically lazy; it directs power to the path of least resistance. If you enter a corner aggressively and the inside wheel unloads (lifts slightly) or hits a patch of gravel, the open differential dumps all the engine’s power to that spinning wheel. You lose acceleration, momentum, and control. The Limited-Slip Differential was created to fix this, but how it achieves the fix matters immensely.

Clutch Type LSDs

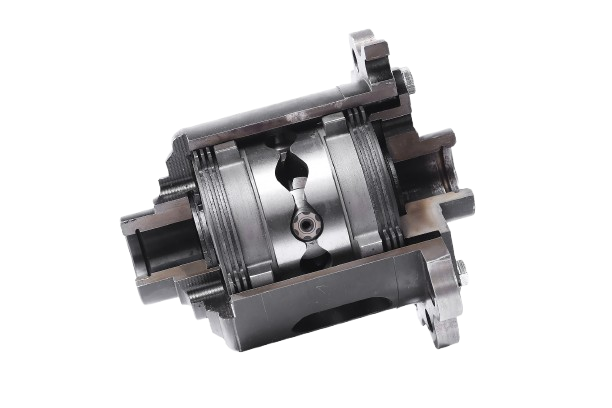

For a long time, the Clutch-type (or plate-type) LSD was the industry standard. Its operation is relatively simple to visualize. Inside the differential housing, alongside the gears, sit stacks of friction discs and steel plates—very similar to the clutch pack found in a manual transmission or a motorcycle wet clutch.

These plates are pre-loaded by springs. When the differential detects a difference in wheel speed, internal pressure rings ramp up, compressing the clutch packs together. This friction locks the two axle shafts, forcing them to turn at the same speed.

The Problem with Friction

While effective at locking wheels, the clutch-type LSD relies on an outdated concept: intentional friction and wear. Every time the differential engages to limit slip, the plates rub against each other. Over time, this friction material wears down, just like brake pads or a transmission clutch.

This leads to several inherent disadvantages that make the clutch-type LSD less desirable for modern vehicles:

- Maintenance Intensity: As the plates wear, the differential’s effectiveness declines. To maintain peak performance, the unit must be periodically disassembled and rebuilt with new clutch packs.

- Specialized Fluid Requirements: These units require specific gear oils with friction modifiers to prevent excessive chatter. Getting the fluid mix wrong can destroy the unit or make it unbearable to drive.

- NVH (Noise, Vibration, Harshness): In tight low-speed turns, such as parking maneuvers, a clutch LSD often binds and releases, causing a “clunking” or “chattering” sound and a jerking sensation through the chassis.

- Heat Generation: Friction generates heat. During prolonged track sessions, clutch-type LSDs can suffer from thermal degradation, altering their locking characteristics mid-race.

While clutch types are still prevalent in professional drifting—where drivers need the rear wheels to lock instantly and aggressively—they are increasingly seen as agricultural and crude for time attack racing, circuit driving, and high-performance street use.

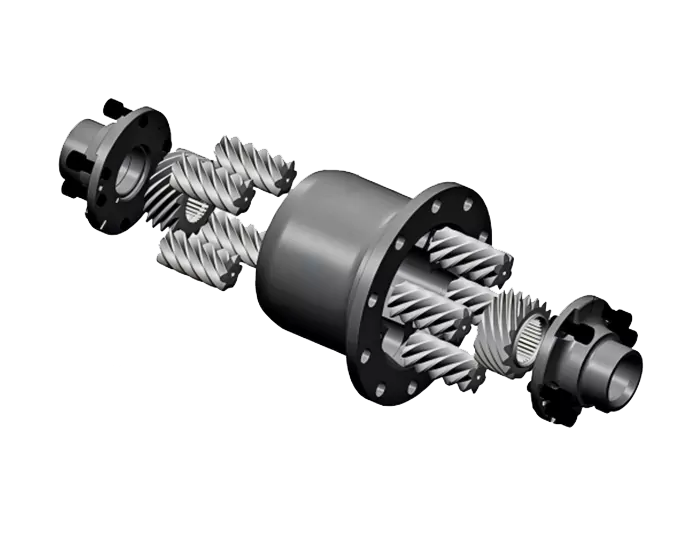

Torsen Helical Differential

How It Works: The Science of Torque Biasing

Why Torsen is the Superior Choice for Performance

1. Progressive and Linear Power Delivery

2. Zero Maintenance and "Set-and-Forget" Reliability

3. Superior Thermal Management

4. Compatibility with Modern Electronics

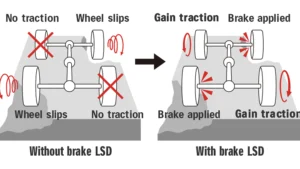

Addressing the "One Wheel in the Air" Scenario

- Suspension Tuning: Performance cars are set up to keep tires on the ground. Unless you are rock crawling or hopping high curbs on a rally stage, lifting a driven wheel completely is rare in circuit and street driving.

- Brake Traction Control: Almost every modern car uses a “brakes-based” traction control system. If a wheel lifts, the car’s ECU applies a slight braking force to that spinning wheel. The Torsen differential perceives this braking force as “traction” (resistance) and instantly multiplies that torque to send it to the wheel on the ground. The synergy between Torsen mechanics and modern electronics effectively negates this historical weakness.

Conclusion: The Engineering Verdict

Upgrade Your Drivetrain with XJXPARTS

At XJXPARTS, we specialize in the precision manufacturing of high-performance driveline components. As a dedicated factory, we control every step of the production process, ensuring that our differentials meet rigorous tolerance standards for durability and performance. Whether you are a distributor looking for reliable inventory or a specialized shop seeking custom solutions, we have the engineering capability to support your needs.