When you are driving on a rain-slicked highway or navigating a gravel-covered backroad, you rarely think about the complex engineering happening beneath your feet. However, the moment one of your wheels hits a patch of ice and starts spinning uselessly while the other sits still, you realize how critical traction is. This is where the electronic differential lock comes into play.

For many drivers and automotive enthusiasts, the term sounds like technical jargon. Yet, the electronic differential lock is one of the most significant advancements in modern vehicle safety and performance. In this guide, we will break down exactly what an electronic differential lock is, how it keeps you moving, and why it is a game-changer for vehicle handling without getting lost in overly academic definitions.

To appreciate why an electronic differential lock is so valuable, we first need to look at a common frustration. Have you ever seen a car stuck in the snow where one wheel is spinning at high speed while the other wheel doesn’t move at all? It looks counterintuitive—why wouldn’t the car send power to the wheel that actually has grip?

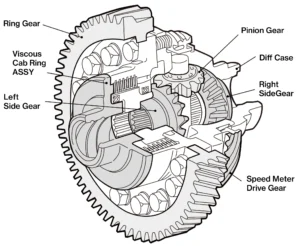

This happens because of the “open differential,” a standard mechanical component in most cars. Its job is to allow wheels to turn at different speeds when you go around a corner. While this is great for smooth turning on dry pavement, it is a disaster on slippery surfaces. The open differential always sends power to the path of least resistance. If one tire is on ice, it has no resistance, so the car sends all the power there, leaving you stranded.

Think of the electronic differential lock as the “brain” that fixes the mechanical “blindness” of a standard differential. Instead of being a heavy piece of metal that physically bolts the two wheels together, it is an intelligent system that uses the vehicle’s existing sensors to manage power distribution.

In simple terms, an electronic differential lock is a software-managed traction solution. It doesn’t wait for you to flip a switch or pull a lever. Instead, it “watches” your wheels through the same sensors used by your brakes. If the system notices that one wheel is spinning much faster than the other (meaning it has lost grip), it steps in to help.

The result? You pull away smoothly from a slippery spot without even realizing the car was working to save you.

In the past, if you wanted a “locked” differential, you had to buy a heavy-duty off-road vehicle with a mechanical locking differential. While those are powerful, they have significant drawbacks for daily driving.

Mechanical locks require extra gears, cables, and heavy casings. An electronic differential lock adds virtually no weight to the vehicle because it uses the hardware already found in the Anti-lock Braking System (ABS). For modern car buyers who care about fuel efficiency and nimble handling, this is a huge advantage.

A manual lock can be dangerous if you forget to turn it off. If you try to take a sharp turn on dry pavement with a mechanical lock engaged, your tires will skip, and you could damage the axle. The electronic differential lock, however, is smart enough to turn itself off the moment you gain speed or start a turn, making it completely “set it and forget it” for the driver.

Because the electronic differential lock relies on clever programming and existing sensors, it allows manufacturers to offer high-level traction control in family sedans and compact SUVs, not just expensive luxury trucks. This makes high-end safety accessible to everyone.

Since this system relies on the braking hardware to manage power, maintenance looks a little different than it does for traditional mechanical gears. If you want to ensure the electronic differential lock stays reliable, you need to focus on two main areas:

Because the system “brakes” the spinning wheel to transfer torque, your brake pads and rotors are technically part of your drivetrain’s performance. Worn-out pads can reduce the effectiveness of the lock. Regular inspections are vital.

In the world of international trade and automotive supply, the electronic differential lock has become a major selling point. Customers no longer just want a car that goes from A to B; they want a vehicle that feels “planted” and secure.

For distributors and retailers, understanding that the electronic differential lock is an integrated system—not just a single part—is key. It involves the ABS module, the sensors, and high-quality braking components. When you supply parts for these vehicles, you aren’t just selling hardware; you are selling the components that allow this safety system to function.

As vehicles become more software-dependent, the demand for precision-engineered components that can handle the rapid-fire demands of an electronic differential lock continues to rise. Whether it’s high-friction brake pads or high-frequency speed sensors, the quality of these individual parts determines how well the “lock” performs in a crisis.

One question we often hear from clients is: “Is an electronic system as reliable as a metal gear?”

The answer is yes, specifically for the types of driving 99% of people do. While a professional rock crawler might still prefer a mechanical piece of steel, the electronic differential lock is more than capable of handling snow, heavy rain, and light off-roading. Its ability to react in milliseconds—much faster than a human could ever react—makes it an indispensable tool for modern road safety.

When it comes to maintaining or upgrading a vehicle’s traction capabilities, the quality of the parts you use is non-negotiable. An electronic differential lock is a precision system, and it requires precision parts to operate at peak efficiency.