Electronic locking differentials, or eLockers, have become a popular upgrade for off-road vehicles and trucks seeking improved traction and drivability in challenging conditions. Unlike traditional mechanical lockers, eLockers use electronic controls to lock and unlock the differential, offering better on-demand traction without compromising drivability on regular roads.

While eLockers provide excellent performance benefits, they require proper maintenance and care to ensure long-term reliability. Neglecting maintenance can lead to premature wear, malfunction, or costly repairs. This article covers essential maintenance tips that help keep eLocker differentials operating smoothly and extend their service life.

Understanding eLocker Differentials

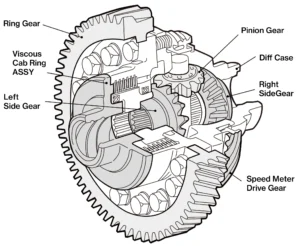

Before diving into maintenance, it’s important to understand how eLocker differentials work. Unlike open differentials that allow wheels to rotate at different speeds, eLockers electronically lock both wheels on an axle together when activated. This maximizes traction on slippery or uneven surfaces.

The system typically includes an electronic actuator, sensors, and control module to engage or disengage the locker. Because of this added complexity compared to mechanical lockers, regular inspection and maintenance of both mechanical and electronic components are critical.

1. Regular Fluid Checks and Changes

Differential fluid is the lifeblood of any differential, including eLockers. It lubricates gears, reduces friction, cools components, and helps prevent corrosion.

Check Fluid Levels: Regularly inspect the differential fluid level according to the vehicle’s service schedule. Low fluid levels can cause overheating and accelerated wear.

Use the Correct Fluid: Follow manufacturer recommendations for the type of gear oil and additives. eLockers may require specific synthetic or limited-slip compatible oils to protect clutch packs inside the differential.

Change Fluid Periodically: Old or contaminated fluid loses its lubricating properties. Most experts recommend changing differential fluid every 30,000 to 50,000 miles, or sooner if exposed to severe conditions such as water crossing or heavy off-roading.

2. Inspect Electronic Components

The electronic aspect of an eLocker is as vital as the mechanical parts. Sensors, wiring, actuators, and control units need periodic inspection.

Check Wiring and Connectors: Look for corrosion, frayed wires, or loose connectors. Water intrusion or road debris can damage electrical parts and cause intermittent locker engagement or failure.

Test Actuator Function: The actuator physically locks and unlocks the differential. If it shows signs of slow or inconsistent operation, it may need servicing or replacement.

Control Module Diagnostics: Modern vehicles allow you to run diagnostics on the electronic locker control module. Regular scans can detect errors early before they affect performance.

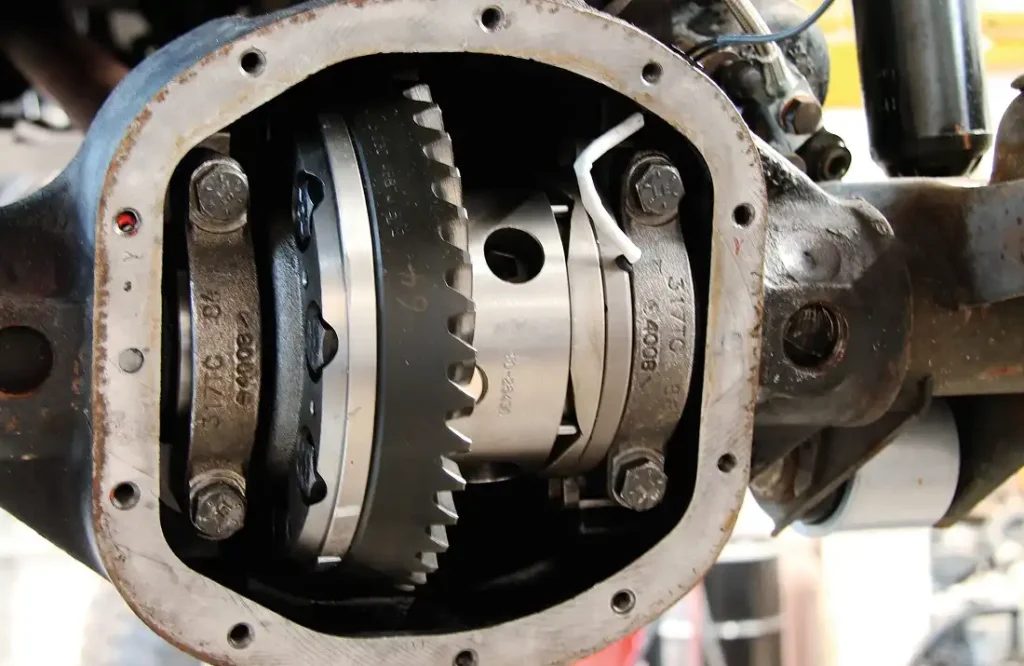

3. Keep Seals and Gaskets Intact

Seals and gaskets prevent fluid leaks and protect the differential internals from contaminants.

Inspect for Leaks: Regularly check under the vehicle for any signs of gear oil leaks near the differential housing, axle seals, or actuator housing.

Replace Damaged Seals: If leaks are detected, replace seals promptly. Fluid loss not only reduces lubrication but also allows dirt and water to enter, which can cause internal damage.

Seal Condition in Wet or Muddy Conditions: Vehicles used in extreme wet, muddy, or off-road environments are at higher risk of seal damage. More frequent inspections are advised.

4. Monitor Differential Temperature

Excess heat is a common cause of premature differential failure.

Use Infrared Thermometer: After off-road trips or heavy towing, measure differential housing temperature. Abnormally high temperatures may indicate lubrication issues or mechanical problems.

Allow Cooldown Time: Give the differential time to cool before performing maintenance or heavy driving to avoid damaging components.

5. Engage eLocker Regularly

While it might seem counterintuitive, regularly engaging the eLocker can help keep the system in good working order.

Prevent Seizure: Prolonged periods without use can cause components, such as the actuator or locking mechanism, to seize or stick.

Functional Check: Regular use allows early detection of any engagement issues, so they can be addressed before a critical failure.

Follow Manufacturer Recommendations: Some manufacturers specify periodic activation even if the vehicle is not used off-road.

6. Avoid Overuse or Misuse

Though eLockers improve traction, improper use can shorten their lifespan.

Do Not Engage on Dry Pavement: Locking the differential on high-traction surfaces causes drivetrain binding and excessive wear.

Use According to Terrain: Reserve locker use for slippery, uneven, or low-traction surfaces as intended.

Mind the Activation Duration: Avoid prolonged engagement beyond necessary time to minimize heat and wear.

7. Inspect Internal Gear Wear and Clearance

During scheduled maintenance or fluid changes, it’s advisable to inspect internal differential gears.

Check Gear Teeth Condition: Look for chipped, worn, or broken teeth on crown wheels, pinions, or spider gears.

Measure Backlash and Gear Clearance: Incorrect gear mesh can cause noise, vibration, and premature wear.

Replace Worn Components: Timely replacement of damaged gears prevents further drivetrain damage.

8. Keep Software Updated

For vehicles equipped with advanced electronic lockers, software updates may be available.

Consult Dealership or Manufacturer: They can provide firmware updates that improve locking algorithms, actuator response, or fault detection.

Update After Major Repairs: After replacing electronic parts, ensure software is properly configured.

9. Use Genuine or High-Quality Replacement Parts

Maintaining eLockers with genuine or reputable aftermarket parts is essential.

Avoid Cheap, Low-Quality Components: Poor-quality actuators, seals, or control modules often fail early and cause additional damage.

OEM or Certified Parts: Using certified components ensures proper fitment, durability, and manufacturer support.

10. Professional Inspection and Service

While many maintenance tasks can be done by experienced DIYers, professional servicing offers additional peace of mind.

Routine Service by Specialists: Differential specialists can perform detailed diagnostics, precision measurements, and advanced repairs.

Preventive Maintenance Plans: Some service centers offer tailored maintenance plans specifically for eLocker-equipped vehicles.

Warranty and Support: Professional maintenance may be required to keep warranty valid.

Conclusion

eLocker differentials provide excellent off-road traction benefits but come with the responsibility of regular maintenance to ensure long-term performance and reliability. By following these essential maintenance tips—including regular fluid changes, inspecting electronic components, protecting seals, and proper usage—vehicle owners can minimize breakdowns and costly repairs.

Regular professional inspection, using high-quality parts, and staying attentive to any signs of trouble will keep the eLocker differential functioning smoothly for years to come. Well-maintained eLockers not only enhance vehicle capability but also contribute to safety and driving confidence in challenging environments.

If you operate or upgrade your vehicle with an eLocker differential, prioritizing maintenance is key to maximizing your investment. Implement these best practices to keep your differential in top shape and ready for any terrain.

FAQs

Q1: How often should I change the differential fluid in my eLocker?

A: It is generally recommended to change the differential fluid every 30,000 to 50,000 miles, but more frequent changes may be needed if the vehicle is used in harsh off-road conditions or exposed to water crossings.

Q2: Can I use any gear oil for my eLocker differential?

A: No. It’s important to use the type of gear oil specified by the manufacturer, often synthetic or limited-slip compatible oils, to ensure proper lubrication and protection of the locking mechanism.

Q3: What are common signs that my eLocker differential needs maintenance?

A: Signs include unusual noises such as clunking or whining, difficulty engaging or disengaging the locker, fluid leaks, or warning lights related to the differential system.

Q4: Can I service the electronic components of the eLocker myself?

A: While basic visual inspections can be done, diagnosing or repairing electronic components often requires specialized tools and expertise. Professional service is recommended for electronic issues.

Q5: Is it bad to leave the eLocker engaged while driving on normal pavement?

A: Yes. Engaging the eLocker on dry, high-traction surfaces can cause drivetrain binding and accelerate wear. It should only be engaged on low-traction or off-road conditions.

Q6: How can I prevent electrical damage to my eLocker system?

A: Regularly inspect wiring harnesses and connectors for corrosion, secure connections tightly, and avoid exposing the electrical components to excessive water or debris.

Q7: Does regular use of the eLocker improve its reliability?

A: Yes. Regular engagement helps prevent mechanical parts from seizing and allows early detection of any potential issues.

Q8: Are there software updates available for eLocker systems?

A: Many modern eLocker systems have control modules that can receive firmware updates. Check with your vehicle manufacturer or dealer for available updates.

Q9: What should I do if I notice fluid leaking from my differential housing?

A: Inspect seals and gaskets promptly and replace any that are damaged to avoid contamination and loss of lubrication.

Q10: Can aftermarket parts affect the reliability of my eLocker?

A: Using low-quality or non-certified parts can compromise the system’s performance and durability. It is advisable to use genuine or high-quality aftermarket components certified for your specific model.