If you’ve ever noticed one wheel spinning while the other barely moves, you’ve seen what happens without a limited-slip differential. Helical LSDs are clever little devices inside your rear or front axle that help both wheels work together. They don’t magically “send power” from one wheel to the other—instead, they use friction to resist wheel spin, keeping your car stable and grippy in corners, on wet roads, or off-road trails. For anyone building, tuning, or upgrading a car, understanding how a helical LSD works can make a big difference in performance.

How Helical LSDs Work?

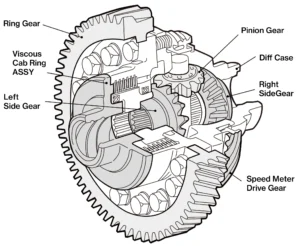

At the heart of a helical LSD are two large side gears connected to the axles and a set of worm-like gears in the center. These center gears interact with each other and the side gears, creating friction that resists differences in wheel speed. When there is no torque applied, the unit allows the wheels to spin almost as freely as an open differential. This means that in a lifted or unloaded condition, one wheel can spin with minimal resistance.

However, when torque is applied, the side gears are pushed outward, and the center worm gears are driven into the pockets of the carrier. The friction generated between the gears and the carrier creates the limited-slip effect, resisting excessive differentiation between the left and right wheels. This frictional engagement is both axial and radial, meaning every gear contributes to the overall resistance.

The Role of Torque Bias Ratio

The effectiveness of a helical LSD is measured by its Torque Bias Ratio (TBR). Common ratios are around 3:1 for typical performance vehicles, while more aggressive setups can reach 5:1. A 5:1 TBR means the differential can maintain torque to the wheel with traction until the inner wheel can only handle 1/5 of the torque compared to the outer wheel.

It is important to understand that helical LSDs do not transfer torque mechanically from one wheel to another. Instead, they apply friction equally to both axles, limiting wheel spin by resisting differentiation. If traction is insufficient or power is excessive, friction decreases, and the unloaded wheel can spin freely. Preloading plays a role here—some LSDs come preloaded from the factory, while others do not, affecting their behavior when one wheel loses contact with the ground.

Many explanations online claim that LSDs “send torque from the slipping wheel to the wheel with traction.” This is not accurate for helical LSDs. The gears inside resist differentiation equally on both sides; the difference in wheel torque is a result of the available traction, not a mechanical transfer of power.

By contrast, traction control systems actively manage wheel speeds by braking the spinning wheel and sending torque to the wheel with grip. Helical LSDs work purely through friction and do not actively redistribute torque.

Why Helical LSDs Are Valuable?

Helical LSDs are similar in function to a sway bar: they connect both axles and share the load equally. This uniform resistance allows vehicles to corner smoothly while minimizing wheel spin. They are particularly beneficial in situations with uneven traction, such as wet roads, gravel, or snowy conditions. By maintaining controlled torque distribution, helical LSDs improve vehicle stability, performance, and driver confidence.

Even clutch-type LSDs with extremely high TBRs, or units locked nearly solid, operate on the same principle: they resist differentiation equally across both wheels. High TBRs allow more torque to be applied to the wheel with traction, but this is due to frictional resistance and available traction, not a torque transfer mechanism.

Conclusion

In summary, helical limited-slip differentials are friction-based systems designed to resist wheel spin and maintain controlled torque distribution. They do not “send power” from one wheel to another but instead apply equal frictional resistance, allowing the wheel with traction to do more work naturally. Understanding TBR, preload, and frictional behavior is key to selecting the right LSD for your vehicle or drivetrain application.

If you are looking for high-quality helical LSDs or custom limited-slip solutions for your vehicles or industrial applications, contact XJXParts today. Our factory specializes in Torsen-type and helical LSDs, providing tailored solutions to meet your performance and traction needs.