In the competitive world of automotive components, sourcing high-quality differential parts is crucial for ensuring customer satisfaction, building long-term business relationships, and maintaining a strong reputation in the aftermarket industry. Whether you operate a wholesale auto parts business, manage a repair shop, or run an eCommerce platform, choosing the right differential components can directly impact your performance and profitability.

This guide will walk you through the essential steps and strategies for sourcing top-tier differential parts, from understanding technical specifications to choosing reliable suppliers and negotiating the best deals.

1. Understand the Types of Differential Parts You Need

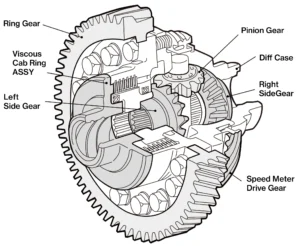

Before reaching out to suppliers, it’s important to define the exact differential components your business requires. The most commonly sourced parts include:

- Ring and Pinion Gears (e.g., Dana 44, Toyota 8″)

- Differential Cases and Carriers

- Limited Slip Differentials (LSD)

- Locking Differentials (Air Lockers, E-Lockers)

- Spools and Mini-Spools

- Bearings, Shims, and Seals

- Axles and Side Gears

Tip: If your customers mostly request upgrades for off-road use, prioritize LSDs, lockers, and ring & pinion sets with enhanced durability.

2. Identify OEM vs Aftermarket Needs

Different markets have different requirements. OEM (Original Equipment Manufacturer) parts offer factory-spec quality, but can be expensive and harder to source in bulk. Aftermarket parts can provide more flexibility in pricing and design.

- OEM Differentials: Ideal for dealers and high-end workshops.

- Aftermarket Differentials: Preferred by tuning shops, 4×4 specialists, and budget-conscious repair centers.

- Heat-treated and precision-machined gears

- Reputable manufacturing origins (e.g., ISO-certified factories)

- Performance testing data (noise level, torque specs)

3. Evaluate Suppliers Carefully

Not all differential suppliers are created equal. Evaluate them on the following criteria:

a. Product Quality

- Are the materials clearly stated (e.g., 8620 steel, forged alloy)?

- Do they offer testing data (e.g., Rockwell hardness, noise dB)?

- Can they provide real-life usage feedback or references?

b. Certifications & Compliance

- ISO 9001, IATF 16949, or other relevant certifications

- Compliance with local and international auto safety standards

c. Lead Time and Inventory

- Can they meet your volume requirements?

- Do they have a stable supply chain to prevent shortages?

d. Communication and Support

- Responsive English-speaking team

- Technical support and documentation availability

Tip: Always ask for samples or a trial order before committing to a large bulk purchase.

4. Compare Pricing and MOQ (Minimum Order Quantity)

Price is important, but not at the expense of quality. Look for balance:

- Transparent pricing models (avoid hidden fees)

- Competitive unit cost based on volume

- Flexible MOQ to test product performance

5. Assess Manufacturing Capabilities

Visiting a factory (physically or virtually) is ideal. Check if your supplier can:

- Handle gear heat-treatment in-house

- Conduct noise and torque testing

- Provide custom engraving, gear ratios, or designs

- CNC machining equipment

- Gleason or Klingelnberg testing machines

- Strict quality control systems (e.g., tooth contact pattern checks)

6. Clarify Warranty, Returns, and After-Sales Policies

Differential failures can be costly for your end-users. Ensure the supplier offers:

- Clear warranty terms (usually 12-24 months)

- Fast replacements for defective products

- Support for installation or compatibility issues

7. Use Digital Platforms to Find Verified Suppliers

You can start your search on:

- Alibaba

- Global Sources

- Automechanika supplier lists

- Google (look for official brand sites like XJXParts)

- Verified badges

- Export history

- Customer reviews or ratings

Pro Tip: Use LinkedIn or forums like Pirate4x4 or IH8MUD to find real user feedback on specific brands or suppliers.

8. Stay Updated with Industry Trends

Auto differential technology is evolving. Stay updated with:

- Electric LSDs and smart locking systems

- Lightweight materials for EVs and high-performance cars

- Shift towards modular, universal-fit gear systems

9. Build Long-Term Supplier Relationships

Once you find a trustworthy supplier, nurture the relationship:

- Provide regular feedback

- Offer insights on local market needs

- Collaborate on exclusive designs or private labeling

Final Thoughts

Sourcing high-quality differential parts requires technical knowledge, supplier vetting, and a long-term strategy. Don’t settle for the cheapest parts—invest in reliable components that reduce warranty issues and satisfy your customers. From LSDs to precision ring & pinion sets, the right sourcing strategy can elevate your auto parts business and set you apart from the competition.

If you’re ready to explore reliable differential suppliers, check out www.xjxparts.com for professional-grade LSDs, lockers, and crown wheel & pinion sets tailored for off-road, drift, and performance applications.