Air lockers are an essential upgrade for off-road enthusiasts and professionals seeking maximum traction in challenging environments. Designed to lock the differential on demand, air lockers provide significant advantages over open or limited-slip differentials. However, like any mechanical system, they can experience performance issues, especially when subjected to harsh terrains or improper installation.

This article covers the most common problems encountered with air lockers, their potential causes, and actionable solutions. Whether you’re a DIY mechanic or a professional installer, this guide aims to save you time, money, and frustration by helping you keep your system performing reliably.

1. Air Locker Not Engaging

Symptoms:

- The locker fails to activate when the switch is flipped.

- No audible click or engagement sound.

- The vehicle behaves as if it’s still running an open differential.

Possible Causes:

- Air supply issues (e.g., compressor failure or insufficient pressure).

- Damaged airline or fittings.

- Faulty solenoid or electrical switch.

- Contamination inside the air locker mechanism.

Solutions:

- Check air pressure: Ensure the compressor is generating sufficient PSI (typically 90–120 PSI is needed). Look for leaks or kinks in the airline.

- Test the solenoid: Use a multimeter to verify if voltage is reaching the solenoid. Replace if unresponsive.

- Inspect fittings and lines: Look for cracks, disconnections, or worn seals. Replace any damaged parts.

- Internal inspection: If all external checks pass, internal damage or contamination may be the issue. Disassembly and inspection by a qualified technician are recommended.

2. Air Locker Not Disengaging

Symptoms:

- The locker remains engaged even after the switch is turned off.

- Difficult steering or tire scrubbing while turning.

- Vehicle feels “locked” during regular driving.

Possible Causes:

- Air pressure is still being supplied to the locker.

- Faulty solenoid sticking in the open position.

- Contaminants causing internal mechanical binding.

- Electrical short keeping the locker engaged.

Solutions:

- Bleed the system: Disconnect the airline to manually release pressure. This should disengage the locker if air is the issue.

- Clean or replace the solenoid: Corrosion and debris can cause sticking. Cleaning may resolve it, otherwise replacement is necessary.

- Electrical inspection: Check the switch and wiring for continuity issues or shorts.

- Inspect internal mechanism: Binding gears or actuator issues may require a teardown and cleaning.

3. Air Leaks in the System

Symptoms:

- Audible hissing near the compressor, solenoid, or differential.

- Locker engages/disengages inconsistently.

- Compressor runs more frequently than usual.

Possible Causes:

- Damaged airline or fittings.

- Loose compression fittings.

- Worn or cracked seals in the differential housing.

- Improper installation or vibration damage.

Solutions:

- Use soapy water to locate leaks: Spray around suspected areas while the system is pressurized.

- Tighten all fittings: Even slightly loose connections can result in leaks under pressure.

- Replace damaged lines: Use high-quality airline tubing rated for automotive use.

- Install vibration-resistant fittings: Especially important for high-impact environments like off-roading.

4. Compressor Overheating or Failing

Symptoms:

- The compressor stops running during activation.

- Burning smell or abnormal noise.

- Locker engagement fails intermittently.

Possible Causes:

- Extended duty cycle beyond rated capacity.

- Poor ventilation or dirty filters.

- Electrical overload or poor grounding.

- Faulty pressure switch.

Solutions:

- Ensure proper compressor sizing: Match the compressor’s duty cycle to your intended use. Dual lockers require more output than single-locker setups.

- Maintain ventilation: Clean filters regularly and ensure the compressor has airflow.

- Inspect electrical system: Proper grounding and wiring are essential to prevent overloads.

- Replace defective parts: Faulty switches or relays can cause cycling failures.

5. Locker Making Noise While Engaged

Symptoms:

- Clicking, whining, or grinding noises.

- Locker engagement accompanied by vibration.

- Noise only present when locker is active.

Possible Causes:

- Improper gear setup or backlash.

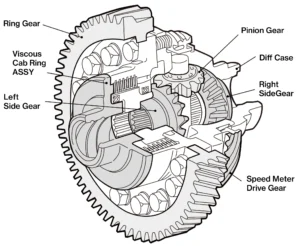

- Worn or chipped ring and pinion gears.

- Poor quality or contaminated lubricant.

- Excessive wear on internal locker components.

Solutions:

- Check gear lash and alignment: Incorrect backlash can lead to gear noise and premature wear.

- Replace worn gears: If ring or pinion teeth are chipped or pitted, replacement is necessary.

- Use high-quality gear oil: Always follow manufacturer specs for viscosity and additives.

- Schedule professional inspection: Persistent or worsening noise can indicate deeper mechanical problems.

6. Electrical Failures

Symptoms:

- Locker won’t engage even though the compressor is working.

- Flickering switch light or complete loss of response.

- Intermittent engagement/disengagement.

Possible Causes:

- Faulty switch or relay.

- Corroded connectors or frayed wiring.

- Weak battery or poor power supply.

Solutions:

- Test switch and relay: Replace if non-functional or showing signs of corrosion.

- Check wiring continuity: Use a multimeter to identify breaks or high resistance in the circuit.

- Secure ground and power: Ensure all grounds are tight and free of rust or debris.

- Use weatherproof connectors: Especially important in wet or muddy environments.

7. Locker Engages but Doesn’t Deliver Full Traction

Symptoms:

- Both wheels are not spinning together.

- Vehicle still gets stuck even when locker is “on.”

- Engagement light turns on but performance doesn’t improve.

Possible Causes:

- Axle shaft damage or differential side gear wear.

- Incomplete locker engagement due to low air pressure.

- Slippage due to worn components inside the locker.

Solutions:

- Inspect axle shafts and splines: Worn or twisted shafts can prevent power from transferring evenly.

- Test air system pressure: Confirm the locker is receiving enough air to fully engage.

- Disassemble for inspection: Internal wear might require rebuilding or replacing specific components.

Best Practices to Prevent Future Issues

To keep your air locker system in peak condition, consider these maintenance habits:

- Perform regular system checks, especially after off-road trips.

- Use only manufacturer-recommended lubricants and parts.

- Protect air lines and wiring from heat, abrasion, and impact.

- Clean electrical contacts and connectors at least seasonally.

- Replace filters and check the compressor’s duty cycle usage.

Final Thoughts

Air lockers offer unparalleled control and traction in difficult driving conditions, but they require proper installation, maintenance, and occasional troubleshooting. By understanding the most common issues and knowing how to address them quickly, you can keep your vehicle ready for any adventure — whether that’s deep mud, rocky climbs, or competitive terrain.

When in doubt, consult your product’s service manual or reach out to a differential specialist. Addressing small issues early can prevent bigger problems down the road and ensure your air locker performs when you need it most.