When it comes to maximizing traction, especially in motorsports, drifting, or extreme off-road conditions, the choice of differential setup can significantly impact performance. Two commonly discussed options are locked differentials and welded differentials. Although both serve the purpose of delivering equal torque to both wheels, their design, application, and long-term reliability are very different.

In this article, we will dive deep into the topic of locked diff vs welded diff, covering how they work, their pros and cons, real-world applications, and which option may be right for you.

What is a Locked Differential?

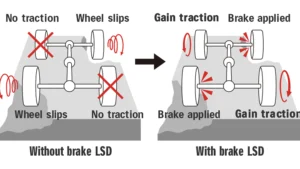

A locked differential is a type of mechanism that forces both wheels on the same axle to rotate at the same speed, regardless of traction differences. Unlike an open differential that allows wheel speed variation (for example, when cornering), a locked differential eliminates this flexibility.

There are different types of locked differentials:

- Automatic lockers – engage and disengage depending on wheel slip.

- Selectable lockers – allow the driver to manually lock or unlock the diff (electronic, pneumatic, or mechanical).

- Spool/Full-time locker – permanently locked, acting like a solid axle.

In practice, locked diffs are highly effective in extreme conditions where maintaining equal torque distribution is crucial, such as rock crawling, drag racing, or competitive drifting.

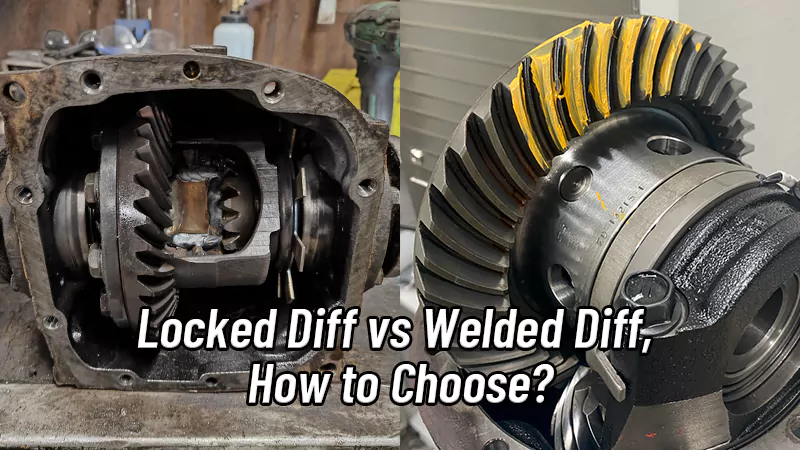

What is a Welded Differential?

A welded differential is essentially an open differential that has been permanently modified by welding the spider gears together. This modification eliminates the gear movement inside the diff, turning it into a solid spool.

The result is the same as having a fully locked diff—both wheels always rotate at the same speed. However, unlike factory-designed lockers, a welded differential is a budget, DIY-style solution.

Because it involves welding, the modification is irreversible and often considered less reliable than a professionally engineered locker.

Advantages of Locked Differentials

- Consistent traction – Both wheels receive equal torque.

- Selectable flexibility – With modern selectable lockers, you can enjoy open-diff comfort on the street and full lock when needed.

- Durability – Designed and manufactured to handle extreme torque loads.

- Professional application – Used in off-road trucks, rally cars, and competitive drift cars.

Disadvantages of Locked Differentials

- Higher cost – Especially electronic and pneumatic lockers.

- Complexity – More moving parts mean possible failures if poorly installed.

- On-road compromises – Full-time lockers reduce maneuverability and increase tire wear.

Advantages of Welded Differentials

- Low cost – Welding is far cheaper than buying a locking differential.

- Drift-friendly – Both wheels spin together, making it easier to initiate and maintain drifts.

- Simple modification – No complicated installation, just welding.

- Grassroots motorsports – Accessible option for budget racers and drifters.

Disadvantages of Welded Differentials

- Unsafe for daily driving – Constant lock causes understeer, unstable handling, and excessive tire wear.

- Stress on drivetrain – Welded diffs can break axles, gears, or bearings due to constant torque load.

- No turning flexibility – Parking lots, tight corners, and wet surfaces become difficult and dangerous.

- Permanent modification – Once welded, you can’t go back.

Which One Should You Choose?

- Choose a locked differential if:

- You want reliability and durability.

- You participate in serious motorsports or off-roading.

- You want the option of selectable locking for mixed-use vehicles.

- Choose a welded differential if:

- You are on a tight budget.

- You only use the car for grassroots drifting or track use.

- You don’t care about tire life, comfort, or daily drivability.

Conclusion

The debate of locked diff vs welded diff often comes down to budget, application, and long-term goals. Welded differentials are cheap and effective for beginners in drifting, but they come with serious drawbacks in reliability and safety. Locked differentials, on the other hand, provide engineered strength and flexibility, making them the preferred choice for professionals and off-road enthusiasts.

If you’re serious about performance and long-term use, investing in a proper locked differential is the smarter choice.

At XJX Parts, we specialize in high-performance differential solutions, including Torsen limited-slip differentials, differential locks, and custom-built options for motorsports, off-road, and OEM applications. As a factory supplier, we provide direct B2B support, competitive pricing, and customization services to match your exact requirements.

Contact us today to discuss your project and get expert guidance on choosing the right differential for your vehicle.