When it comes to traction, cornering, and handling stability, the differential is one of the most underrated yet critical components of a vehicle’s drivetrain. Among the many limited-slip differential (LSD) technologies available today, the Torsen differential—short for Torque Sensing—has built a strong reputation for its mechanical precision and long-term reliability.

But is a Torsen differential actually better than other types of LSDs? And more importantly, is it the right choice for your vehicle platform or your customer market?

Let’s dive deep into the engineering behind it, explore real feedback from drivers, and analyze whether Torsen LSDs truly live up to the hype — especially in the context of OEM and aftermarket B2B applications.

What Is a Torsen Differential?

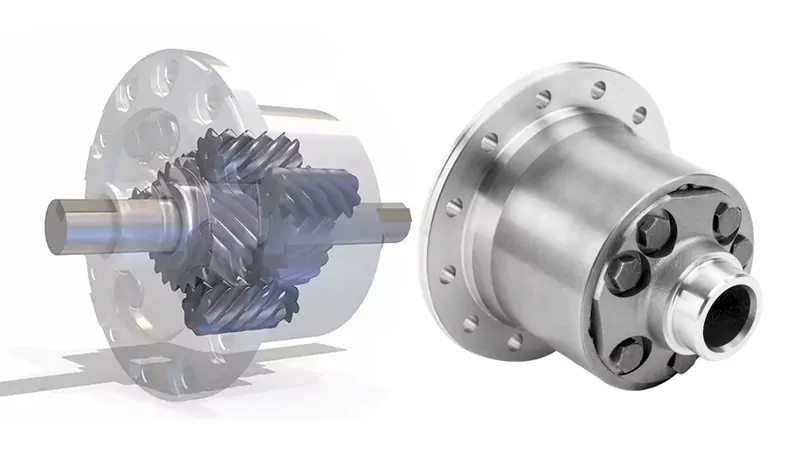

The name “Torsen” comes from the phrase Torque Sensing — and that’s exactly what it does. Unlike clutch-type LSDs that rely on friction plates, or electronic lockers that depend on actuators, a Torsen LSD uses a series of worm gears and worm wheels to sense torque differences between the drive wheels.

Here’s how it works in simple terms:

- When both drive wheels have similar traction, torque is distributed evenly.

- When one wheel begins to lose grip, the internal gear mechanism redirects more torque to the wheel with better traction — instantly and mechanically, without any electronic delay or friction clutch engagement.

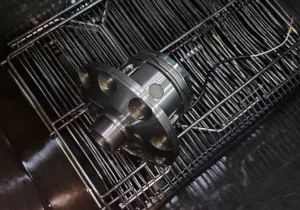

This gear-driven torque bias allows continuous and automatic adjustment of power delivery. Because the operation is purely mechanical, the system responds instantly and is maintenance-free under normal use.

Most Torsen units are designed with a torque bias ratio (TBR) between 2.5:1 and 4:1, meaning the system can send up to 4 times more torque to the wheel that still has grip. This makes it particularly effective for road performance, mild off-road use, and everyday driving where reliability and stability matter most.

Why So Many Automakers Choose Torsen LSDs?

Torsen differentials have been widely adopted by leading OEMs — Audi, Toyota, Ford, and many more — precisely because they offer predictable performance with low maintenance requirements. For factory-level engineering, that’s gold.

Key advantages include:

1. Seamless and Linear Torque Transfer

Unlike clutch-type LSDs, which can feel abrupt when locking and unlocking, Torsen units deliver a progressive locking effect. This gives smoother transitions through corners, which translates to better stability for everyday drivers.

2. Maintenance-Free Operation

Since there are no clutches or friction plates inside, the Torsen design doesn’t wear down easily. That’s a major cost advantage for fleet operators, OEMs, and vehicle manufacturers focused on long-term reliability.

3. Silent, Efficient, and Durable

With precision-machined worm gears and no need for special additives in gear oil, Torsen LSDs operate quietly and efficiently for hundreds of thousands of kilometers.

4. Better Grip Without Electronic Complexity

In today’s market, electronic LSDs and traction control systems are common — but they rely on sensors and braking intervention. A Torsen LSD achieves the same goal mechanically, offering a pure, immediate response without electronic delay or overheating brake components.

Insights from the Drifting Community

On Reddit’s r/Drifting forum, a post titled “Are Torsen diffs really that bad for street cars?” sparked an interesting debate among real enthusiasts and track-day drivers.

Their opinions reveal both sides of the story, and help us understand why Torsen LSDs are loved by some, and criticized by others.

One user explained:

“The Torsen is constantly changing the specific amount of torque going to each wheel, based on friction resistance on each wheel. In contrast, a welded diff is completely predictable.”

That’s true, because a Torsen is designed to react to traction, not to lock both wheels regardless of conditions. For drifting, where drivers rely on fully locked behavior, that makes it harder to predict slide initiation and exit.

Another user added:

“When you let off the throttle, it turns into an open diff, so you really need to beat on the car to keep linking drifts.”

This highlights a key behavior: a Torsen requires constant torque input to keep distributing power. When off-throttle, it behaves more like an open differential — perfect for grip driving, but less ideal for drift linking.

However, another experienced racer countered with a positive take:

“Torsens are garbage for rally… On the other hand, they’re absolutely awesome for road racing and other grip driving.”

This aligns with what engineers already know, the Torsen excels in high-grip, balanced traction environments such as tarmac circuits, highway performance, and street applications.

Limitations and What You Should Know

To be objective, the Torsen is not perfect for every scenario. Understanding its limitations helps B2B clients choose the right product for their market.

Zero Torque to a Zero-Grip Wheel

If one wheel is completely off the ground or on ice, a Torsen cannot transfer torque because its mechanism depends on resistance. Engineers often pair Torsen LSDs with traction control or electronic brake assist to solve this.

Not Ideal for Extreme Drift or Off-Road

For pure drift setups, many tuners still prefer clutch-type 2-way LSDs or fully locked units. Torsen is built for stability and control, not constant oversteer.

Similarly, for off-road vehicles that frequently lift a wheel, mechanical lockers or hybrid “Torsen + locker” systems are more effective.

Torque Bias Ratio Is Fixed

The TBR is designed into the geometry and can’t be adjusted afterward — unlike clutch LSDs that can be preloaded differently. This is not an issue for OEM users who value consistency, but it’s worth noting for tuners.

Conclusion

So, Is a Torsen Differential Better?

The short answer: Yes — if your goal is balanced traction, reliability, and low maintenance.

The Torsen differential is one of the best mechanical LSDs ever designed for street, performance, and OEM applications.

However, for extreme drift or off-road use, where full locking is essential, it’s not the ideal standalone solution. In those cases, a Torsen + Locker or electronically controlled LSD offers a superior balance between flexibility and traction.

For B2B manufacturers, importers, and distributors, the Torsen design remains a benchmark for mechanical simplicity and long-term durability, a clear win for modern drivetrain engineering.

At XJXParts, we specialize in Torsen-type limited-slip differentials, differential lockers, and ring & pinion gear sets. With years of OEM experience and advanced CNC machining capability, we provide custom-built torque bias ratios, precision gear pairing, and bulk supply solutions for global vehicle platforms. Contact XJX Parts today to discuss your requirements and start your OEM collaboration.